Everyone knows that maximizing pollination is one of the more effective ways to boost crop yields. However, most take a hands-off approach and just let Mother Nature do her thing. The truth is that, beyond hand-pollination, there are few proven ways to improve pollination success. Startup “PowerPollen” thinks it can change all that with its new autonomous, AI-enabled, precision pollen application machine that optimizes pollen distribution and claims up to double yield improvement.

Grain crops like corn and wheat generally rely on wind to transfer pollen. A lot can go wrong during this critical stage of development, though. Pollination can be hindered by too hot and too cold temperatures, too much or too little rain, high humidity, excessive cloud cover – basically all the typical weather conditions experienced throughout a Midwest growing season!

In corn, pollination happens when tassels emerge from the top of the corn plant, then open to disperse pollen on the silks, which emerge from the immature corn ear. Each individual silk is a potential kernel of corn, so if a silk doesn’t receive a grain of pollen, no kernel will form in that space on the ear. For wheat, plants start the pollination phase once they begin flowering. It can take three to five days for full pollination, and the number of kernels per head is determined by the number of flowers that are pollinated.

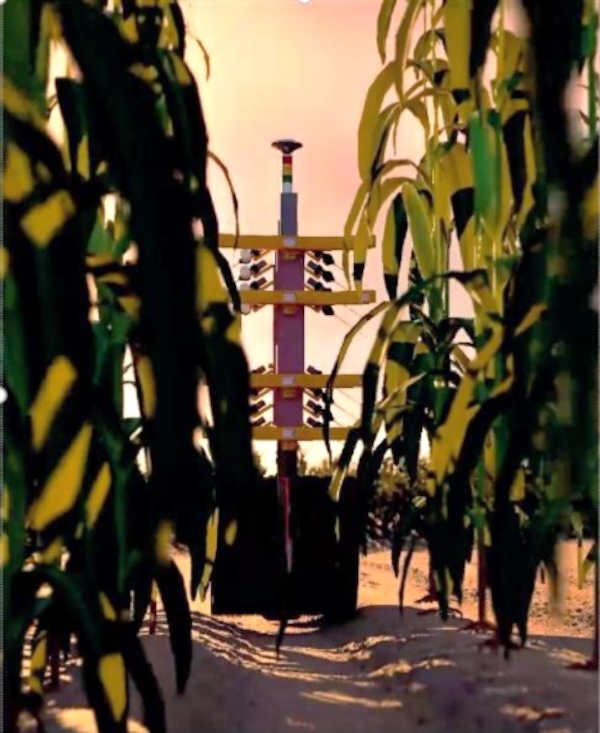

PowerPollen’s system starts by tracking crops through the maturation cycle in order to pinpoint the ideal pollination window. Once mature, the PowerPollen vehicles, which travel row-by-row in coordinated fleets, collect the pollen from tassels. The pollen is quickly cleaned, preserved, and stored until the ideal pollination window opens, at which time the autonomous vehicles travel back through the fields, distributing pollen evenly throughout the crop.

PowerPollen, earlier this year, received a patent for its pollen preservation technique, which blends solid particulates with fresh pollen grains to protect their viability during storage. The process, developed over the last decade, prevents the live pollen grains from contacting material leaked from dead pollen grains, which dramatically extends their viability, according to Jason Cope, PowerPollen’s Chief Intellectual Property Officer. “Our discoveries changed the previously held notion that row crop pollen was not capable of being stored for any duration,” notes Cope.

PowerPollen’s system initially collected and distributed pollen using a tractor attachment. The new autonomous system is designed “to work in literally any environment, from smallholder farms in India to massive commercial operations in Brazil,” said Cope. The vehicle also utilizes AI-powered field vision and proprietary data-gathering capabilities that enable growers to capture valuable crop performance insights while applying pollen precisely where it’s needed. Its compact design improves maneuverability in-field as well as the ease of transporting the units to other commercial acres. The battery-powered core of the system supports long operation times with minimal soil compaction and canopy damage.

PowerPollen is headquartered in Iowa with additional research operations in Puerto Rico and Texas. Learn more about how PowerPollen’s on-demand pollination technology works at its website HERE. (Sources: PowerPollen, CropLife, Associated Press)