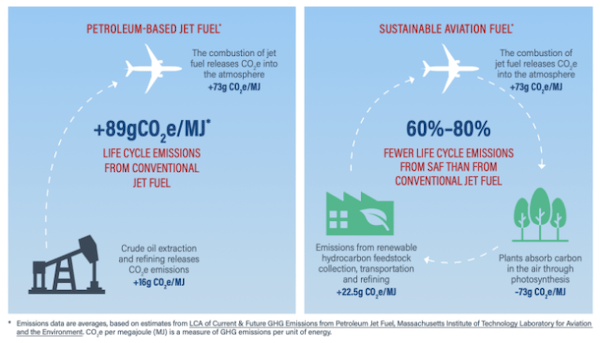

Honeywell has announced a new technology to make aviation fuels cleaner and cheaper than ever by converting ethanol into sustainable aviation fuel (SAF). Aviation is considered among the most difficult to wean off fossil fuels as planes require enormous amounts of energy to take off and stay in the air. But according to Honeywell, its new ethanol-to-jet fuel process can reduce greenhouse gas (GHG) emissions by -80% compared to petroleum-based jet fuel, depending on the feedstock used. It could also dramatically increase the demand for ethanol-based fuels.

Sustainable fuels made up less than 0.1% of the 91 billion gallons of global jet fuel used in 2019. But Honeywell says that’s more to do with cost than demand. Current technologies are typically HEFA (Hydroprocessed Esters and Fatty Acids)-based, meaning they use feedstocks like vegetable oils and used cooking oils. These feedstocks tend to be in shorter supply and thus very costly. Used cooking oil, for example, is trading above the price of jet fuel.

Honeywell’s new technology, by contrast, works with widely available corn-based, cellulosic, or sugar-based ethanol. Kevin O’Neil, senior business leader, renewable fuels, at Honeywell Sustainable Technology Solutions, pointed out in a recent interview that their process could help fill the growing demand hole as internal combustion engines are replaced by electric vehicles.

What’s more, plants currently using Honeywell’s technology can be modularized offsite, enabling lower costs and faster and less labor-intensive installation. According the Honeywell, this approach allows producers to build out new SAF capacity more than a year faster than traditional construction. The new technology would also enable oil refiners and other fuel producers to convert current or idle facilities into SAF production plants, it said.

In 2021, President Biden challenged the industry to generate enough SAF to fully satisfy US aviation jet fuel demand by 2050. There are no major technical problems with 100% SAF, which has completed numerous successful trials, including a commercial flight by United Airlines. According to experts, the main caveat is that 100% SAF needs the latest generation of engines. Currently, a maximum 50-50 blend with fossil jet fuel is allowed. To reach the 100% SAF target, the International Air Transport Association (IATA) projects 23 billion liters (6 billion gallons) of SAF will be needed by 2030, and 449 billion liters (119 billion gallons) by 2050.

Tax incentives in the US and regulatory targets in the EU could further drive demand over the next several years and decades. Starting in 2023, under the Inflation Reduction Act (IRA) passed earlier this year, US fuel blenders will be eligible for a $1.25 to $1.75 tax credit per gallon of SAF that generates a more than 50% reduction in GHG emissions. The IRA also created a new clean fuels production tax credit between $0.35 and $1.75 per gallon for SAF with a greater than 50% reduction in GHG emissions. In the European Union, a plan in the works would increase the share of sustainable fuels at the bloc’s airports from a minimum of 2% in 2025 to at least 63% by 2050. (Sources: BiofuelsDigest, Reuters, Technical Ripon)